Raman 785nm Lasers

Description

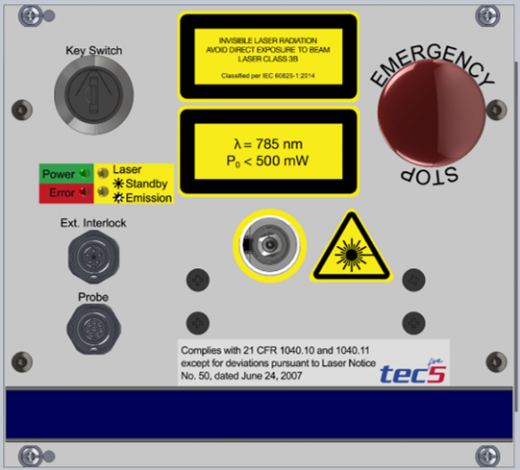

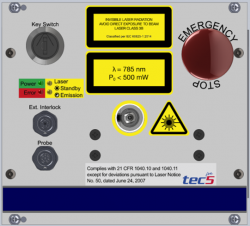

tec5USA delivers 785nm lasers and their corresponding drive electronics for all OEM Raman systems as well as for our integrated turnkey solutions and online analyzers. The Raman 785nm lasers are built on Volume Bragg Grating (VBG) technology, ensuring high wavelength accuracy, linewidth and stability thanks to the TE-stabilized laser diode and the current monitoring feedback circuit. With an output power of up to 500mW, they are geared for both OEM analytical applications and industrial measurements.

For applications in hazardous or explosive environments, additional, stringent safety standards and norms (ATEX, UL, CSA, IECEx) must be followed. One specific aspect of the norms is to limit the laser power at the output of the Raman probe to less than 35mW. tec5USA has developed the proper architecture, both from a hardware and software perspectives, to ensure adherence to these norms and guarantee certification.

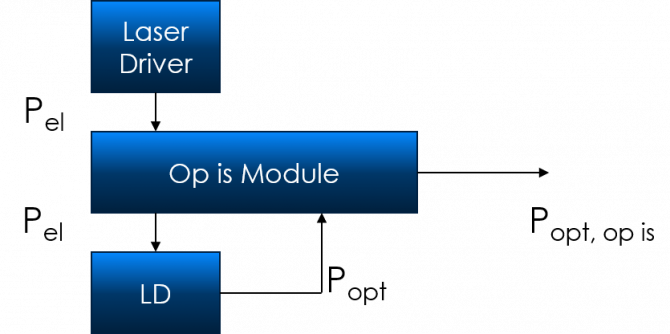

tec5USA’s optically intrinsically safe strategy is the foundation of our Raman laser integration for Process Analytical Technology, where an “op is” module monitors and limits the laser power that is controlled by the laser driver. System is switched off if power is exceeded.

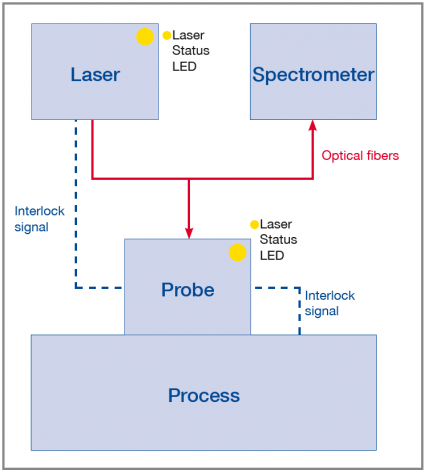

Regardless of the power output, safety plays a major role when considering instrumentation for installation in industrial plants or processes. In the evaluation of Raman systems, performance of the spectrometer is the focus. When the system is transferred from a laboratory environment into a process, some additional safety considerations must be taken into account. A safety concept, which also envisions a distributed installation of components, is required.

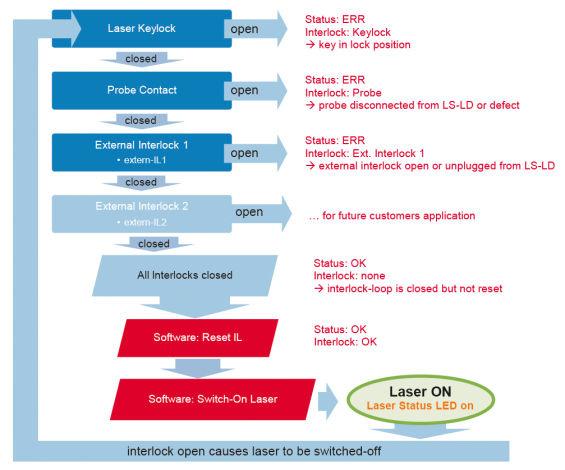

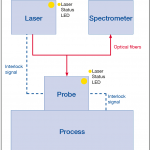

Using a 785 nm laser, the emission is beyond the sensitivity of the human eye and therefore has a high potential to permanently damage the retina. Under process control conditions, the laser is operated continuously 24/7, but not all staff on a plant may be trained in laser safety. A safe operation mode, covering laser safety issues, is ensured using an elaborated interlock system. The employed interlock-loop prevents access to laser radiation by untrained personnel. This interlock-loop ensures deactivation of laser if the optical path is interrupted, or if the Raman probe head is unmounted from the protective probe chamber. This interlock-loop covers the complete pathway of the laser radiation, from the source to the sample, which may be up to several meters away. The operator is fully responsible for ensuring a proper connection of the laser fiber to the instrument as well as for ensuring a safe connection of the Raman probe head to the process.

tec5USA Raman systems support an interlock-loop consisting of up to four interlock-interfaces: Laser-Keylock, Probe Contact Interlock and two external interlocks at the measurement volume or sampling location. If all interlocks are connected, the laser can be switched on. Since the interlocks are continuously checked via electronics, an interruption of one interlock causes the electronics to switch-off the laser.

Features

- Built on Volume Bragg Grating (VBG) technology.TE-stabilized laser diode and current monitoring circuit for wavelength and power stabilization.

- Integrated Automatic Power Control with internal photodiode feedback for output power closed-loop monitoring.

- USB and Analog circuit interfaces available for TE setpoint, Current, Enable/Disable/Interlock functions.

- Redundant architecture of safety and interlock circuits for user protection.Op is version available for hazardous and explosive environments and adherence to regulations.

Advantages

- Adjustable power by current or by PWM, from 5 to 100% of nominal output.

- Outstanding wavelength stability (+/- 5pm typical).

- High optical power stability (< 1 % pk-pk).

Specifications

- Output power Up to 500mW

- Wavelength centering 785.0 nm +/- 0.5nm

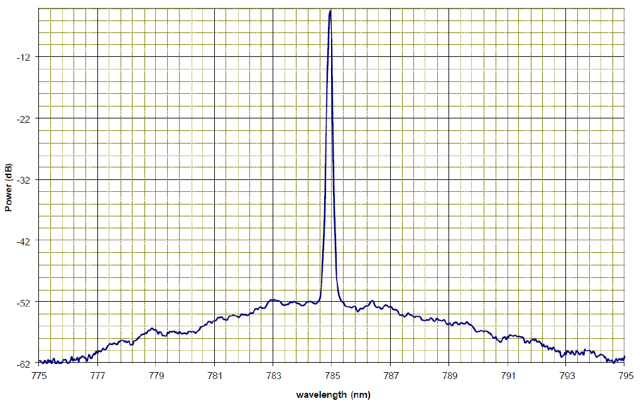

- Spectral linewidth (typ.) < 0.15 nm FWHM

- Wavelength stability (max.) +/- 5 pm

- ASE suppression (typ.) 40 dB

- Optical power stability (typ.) < 1% pk-pk

- Noise (10Hz-10MHz) < 0.25 % rms

- Power adjustability 5-100 %

Improving production for your business

Developing Customer Specific OEM Product Solutions

Cutting-Edge Technology

Unwavering Customer Support

Solution Provider

PRODUCTS & SOLUTIONS

OEM Components and Turnkey Solutions to help you save costs

-

![probes other optical interfaces]()

Probes & Optical Process Interfaces

-

![Optical Fibers & Assemblies]()

Optical Fibers & Assemblies

-

![Electronics Multiplexers & Optical Fiber Switchers]()

Electronics Multiplexers & Optical Fiber Switchers

-

![OEM Light Sources]()

OEM Light Sources

-

![Operating Electronics]()

Operating Electronics

-

![Imaging Sensors]()

Imaging Sensors

-

![Diffraction Gratings]()

Diffraction Gratings

-

![Optical Benches & Spectrometer Modules]()

Optical Benches & Spectrometer Modules

tec5 Custom OEM and Turnkey Solutions

Enabling real-time process verification through rapid in-line spectroscopy

see also those other